In the past few years, the international manufacturing landscape has experienced significant transformations, prompting companies to reevaluate their operations in China. The factors driving this shift are multifaceted, comprising economic, political, and social dimensions. As businesses deal with trade tensions, rising labor costs, and an increasingly complex regulatory environment in China, many are exploring alternative manufacturing locations that offer greater flexibility and resilience.

The decision to move manufacturing out of China is not merely about reducing costs; it includes the need for innovative product design and manufacturing strategies that align with changing consumer demands. By diversifying manufacturing move manufacturing out of china , companies can not just mitigate risks associated with overreliance on a single country but further enhance their ability to respond to market needs with agility. This evolving approach is leading to a new era of manufacturing that prioritizes sustainability, technology integration, and a closer connection to customers globally.

Global Changes in Production

During the past few years, the field of global manufacturing has seen significant changes. While businesses seek to minimize risks and adjust to developing market demands, the move from China has grown increasingly obvious. Factors such as increasing labor costs, geopolitical tensions, and supply chain disruptions have driven companies to reconsider their manufacturing strategies. This assessment is driving a movement towards diversification and the exploration of alternative manufacturing hubs across Asia, Europe, and even the Americas.

The implications of relocating manufacturing operations extend beyond just cost savings. Companies are now prioritizing agility and resilience, ensuring that they can respond swiftly to shifts in consumer preferences and global market conditions. Product design and manufacturing are being aligned more closely with local production capabilities, allowing more sustainable practices and reduced lead times. As manufacturers venture into new territories, they are finding innovative solutions that enhance their competitiveness while fostering partnerships in developing markets.

Additionally, as digital technologies reshape the manufacturing landscape, businesses are leveraging advancements such as automation and artificial intelligence. These innovations allow for more efficient production processes and higher quality products, no matter the geographic location. The shift away from China also encourages manufacturers to invest in research and development in regions that advocate for progressive policies and skilled labor forces, eventually leading to a more balanced and dynamic global manufacturing ecosystem.

Obstacles of Moving

Moving manufacturing operations from China presents several substantial challenges that companies must handle carefully. One of the primary issues is the likelihood disruption of supply chains. Businesses that have established extensive networks in China may find it hard to recreate these connections in new locations. Disruptions can lead to setbacks in production, increased costs, and possible loss of market share if competitors sustain stable operations.

Another challenge lies in the differences in regulations and local compliance requirements that differ by country. Each region has its own set of rules governing labor practices, environmental standards, and taxation, which can hinder the transition for companies familiar to Chinese manufacturing practices. Understanding these regulations is crucial, as non-compliance can result in legal repercussions and damage to the company’s reputation.

Additionally, there is the issue of talent acquisition and workforce training. While some countries may have skilled labor available, companies might face difficulties in finding workers with the specific technical expertise needed for product design and manufacturing. The relocation process often requires investing in training programs to ensure that the workforce meets the desired standards, thereby adding to the overall cost and complexity of the transition.

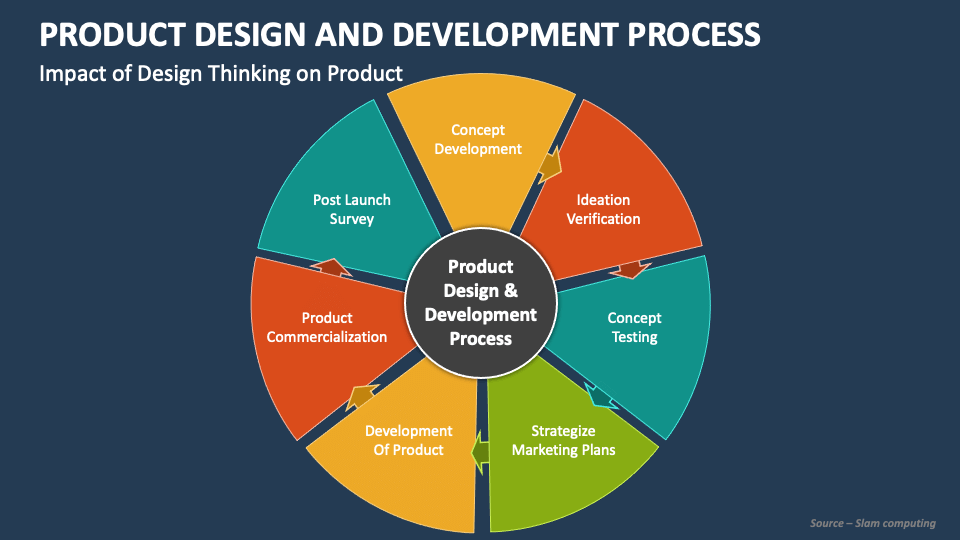

Creative Strategies for Item Development

As firms review their production approaches, novel solutions in item development prove to be crucial. Moving manufacturing from China creates an opportunity to reimagine conventional development methodologies. By employing state-of-the-art tools such as 3D printing and computer-aided modeling, organizations can create prototypes swiftly, reducing timelines and allowing rapid evaluation and iteration. This nimbleness allows businesses to respond to consumer needs more effectively while also improving their asset management.

In furthermore to tech progress, a shift in geography can promote collaboration with regional creators and engineers who provide valuable insights into consumer tastes. This localized approach not only improves the goods' relevance but also encourages sustainable practices through shorter supply chains. Producers can adopt eco-friendly materials and processes, making their items more appealing to environmentally conscious consumers, which is evermore vital in the current market.

Finally, embracing a customer-focused development approach can substantially influence the performance of items produced outside of China. Firms that engage customers in the development process gather valuable insights, helping to develop items that truly satisfy customer needs. This method stimulates creativity and syncs production methods with customer expectations, ultimately driving contentment and commitment. By moving production activities, organizations can harness these groundbreaking strategies to develop products that stand out in an intensely competitive market.